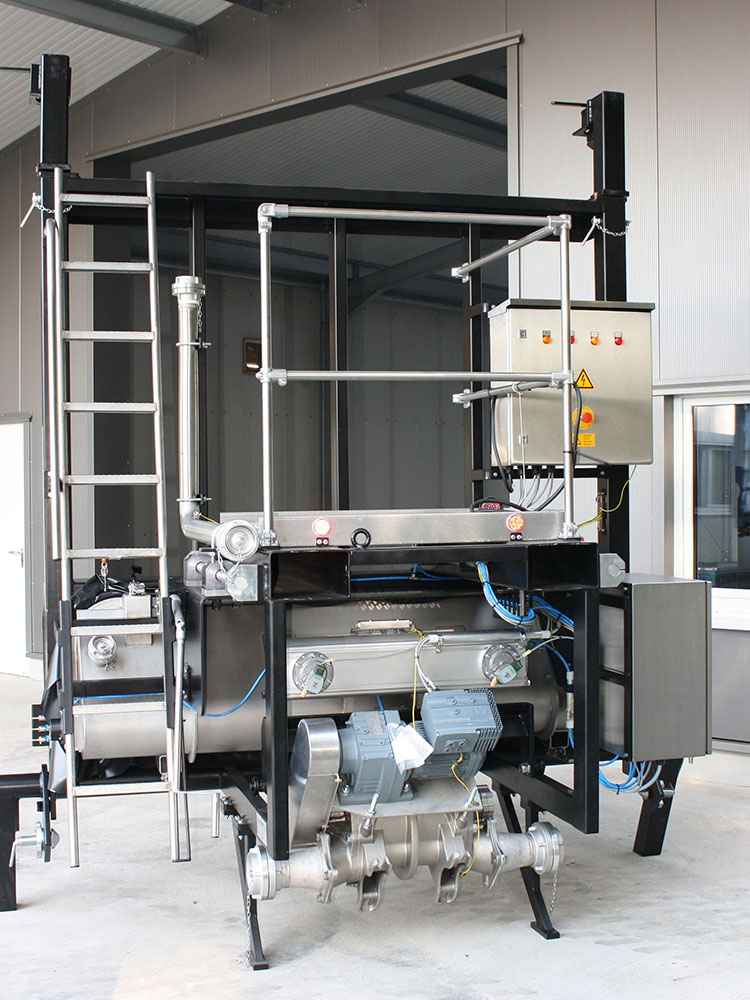

The siloadmaxX® unloading system CQF (Container QuickFlow)

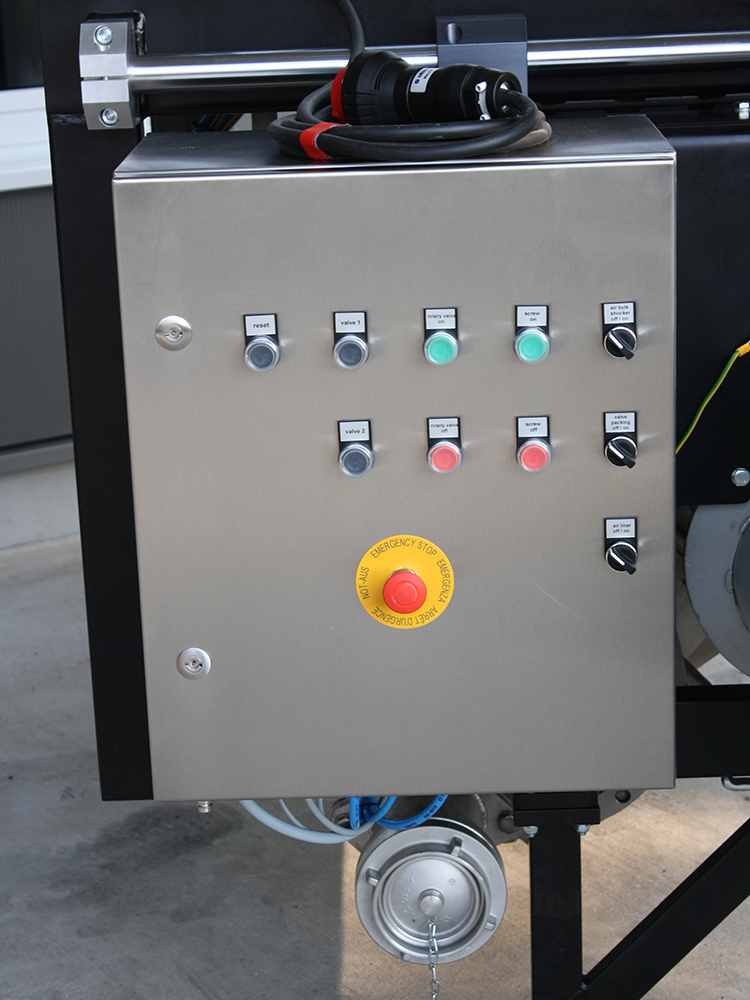

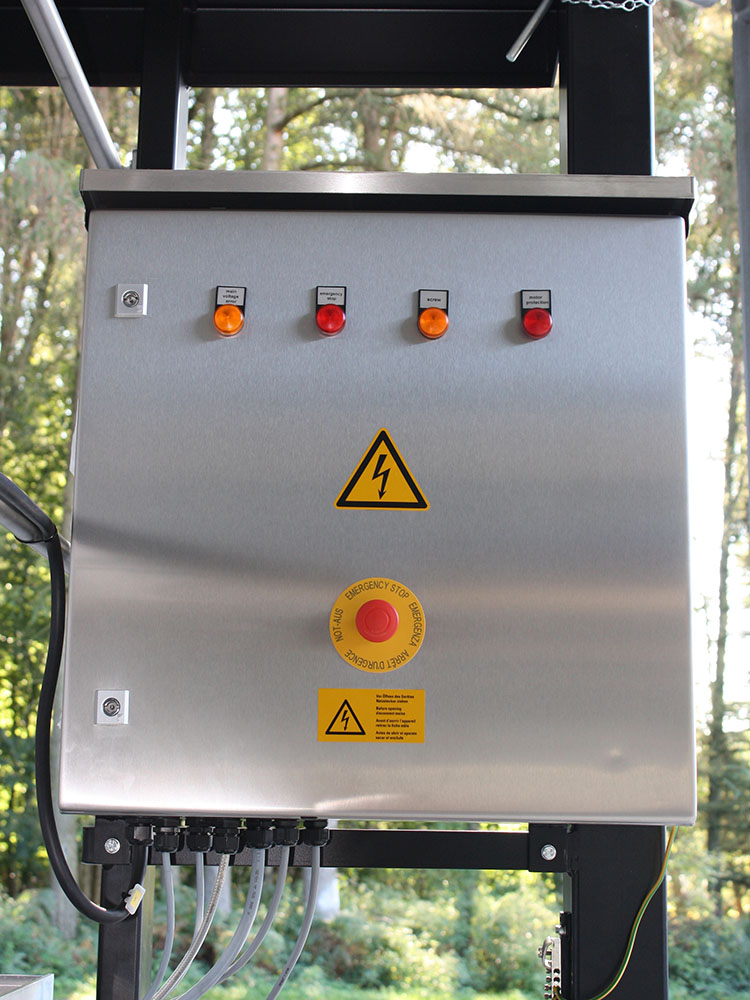

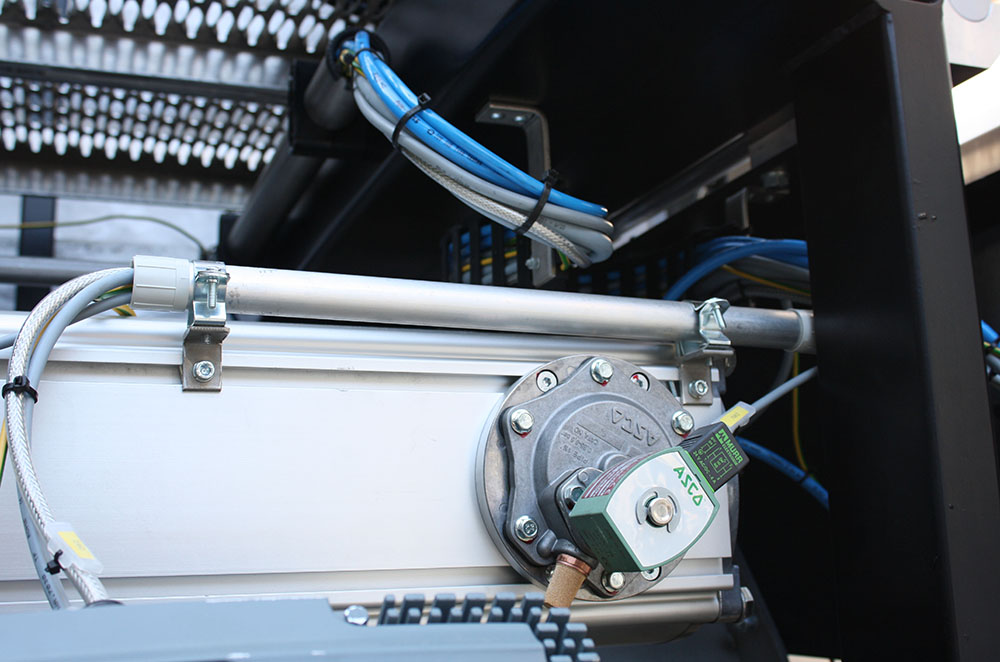

- Closed unloading system reduces danger of dust explosions significantly

- Tipper chassis for tippen directly from the truck

- Discharging with tilting

- Allows dosed unloading with tilting table on support legs and integrated weighing system

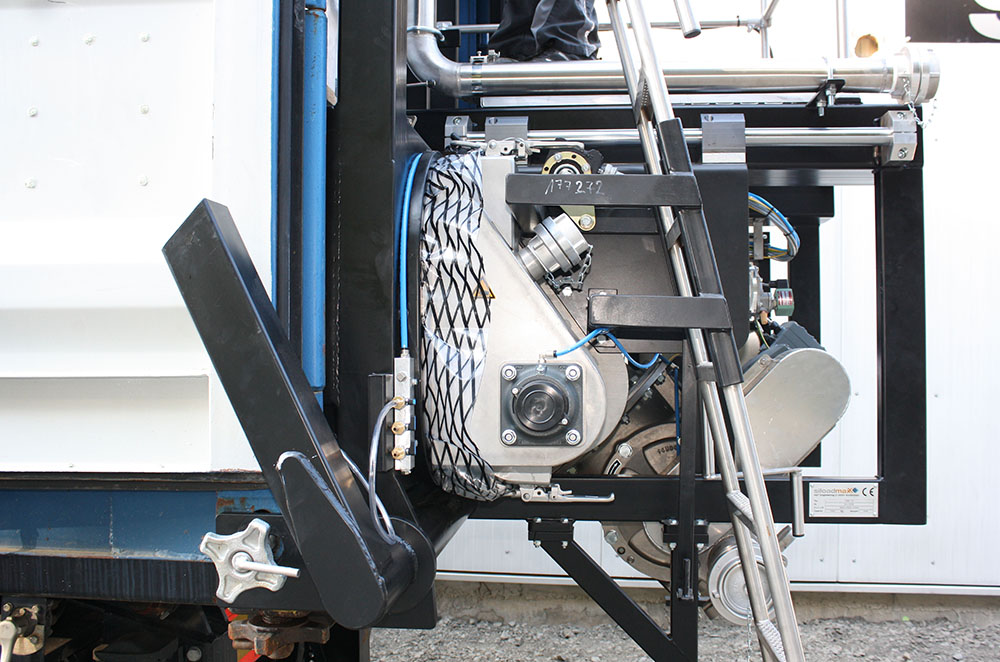

- Mobile solution (unloading portal) to be fixed onto the container

- Dust free unloading with protection against external pollution and other influences

Unloading directly into a silo tower

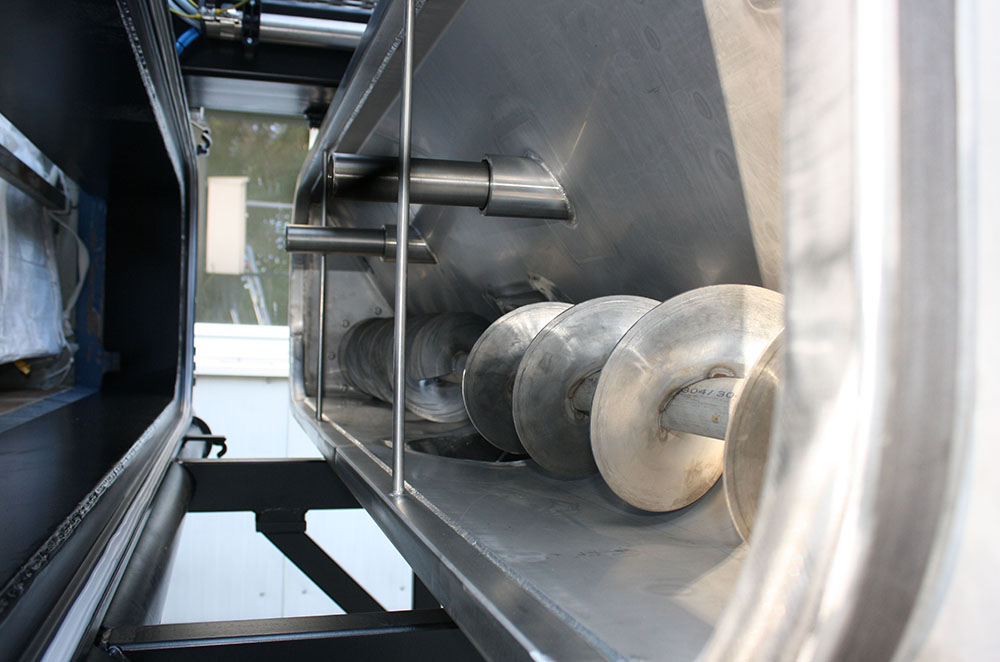

The typical unloading situation is the unloading into a silo tower in which the material is being conveyed from a container into the silo tower. The unloading portal will be hung onto the container which itself is being lifted with decreasing filling grade.

Unloading into underground bunker

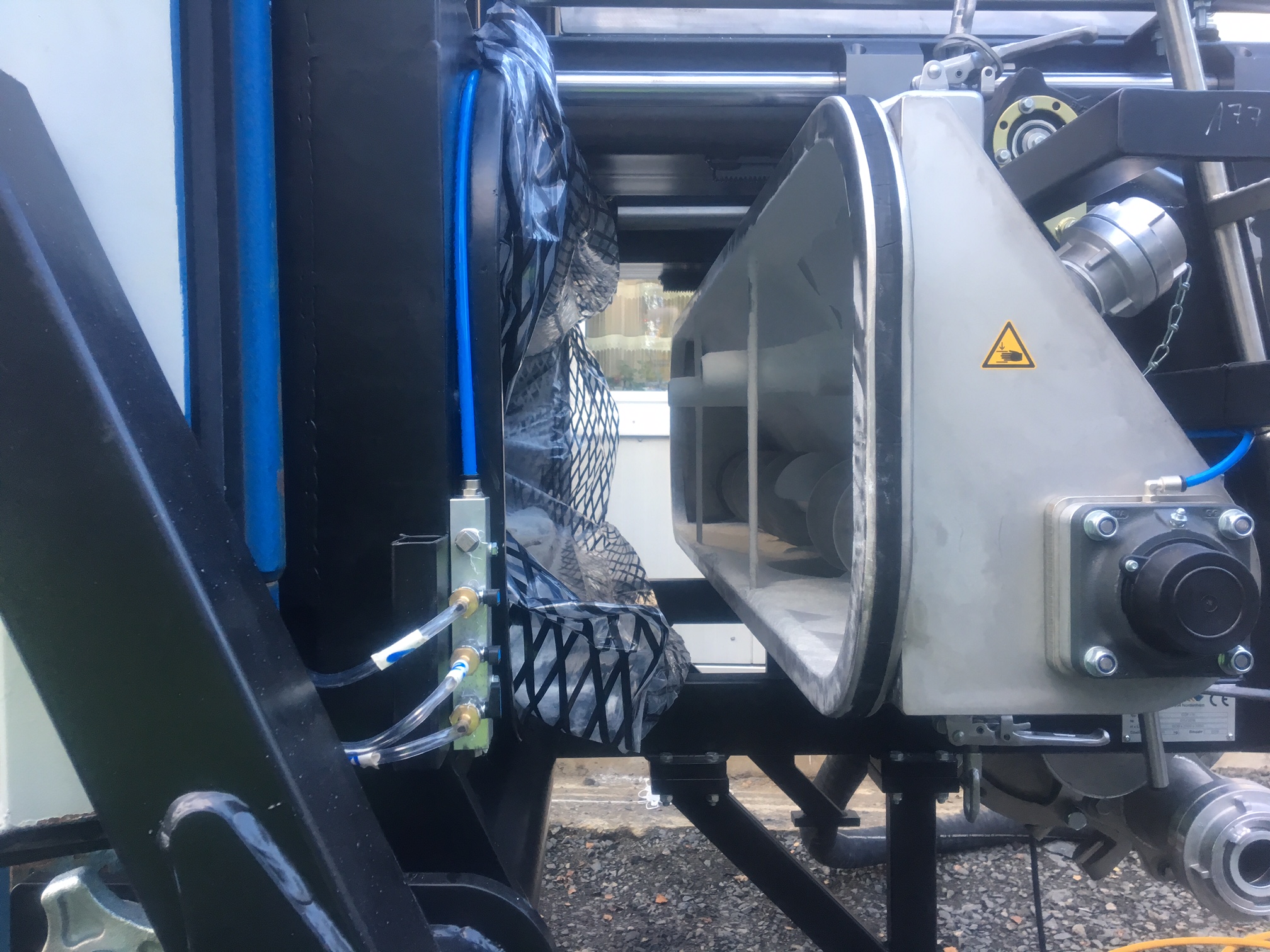

The bulk good is being unloaded from a Standard-ISO-Container with the aid of gravity.

Unloading into the production

The siloadmaxX®-system can eliminate process steps for unloading bulk goods into a variety of storage spaces and can be adapted to the conditions of unloading material directly into the production plant.

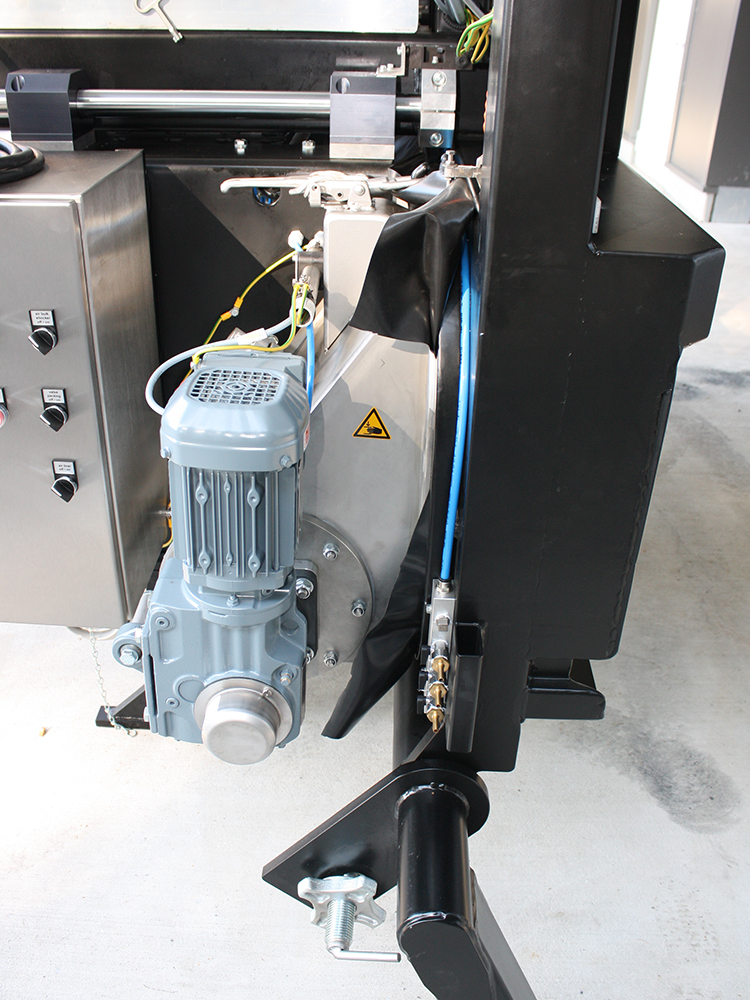

Unloading with a tilting table system

The option of a tilting table system is suitable for all areas where tilting chassis systems cannot be used or in regions where they are not permitted. Our siloadmaxX®-system supports this option in all regions of the world.

Unloading from tilting table into the production

Unloading into the production plant is also possible with the tilting table system.